Caulk Lines: How to Create Clean Lasting Seals in Every Room

Caulk Lines are the small visible seams that make a big difference in the look and function of trim joints, tubs, sinks and windows. A crisp straight line of caulk can turn a tired looking joint into a sharp finish and can prevent water damage and air leaks. This guide explains what makes great Caulk Lines, how to prepare surfaces, how to apply materials for a neat finish and how to maintain sealed joints for long life.

Why Caulk Lines Matter

Caulk Lines are more than cosmetic. Properly applied caulk stops moisture from entering gaps that can rot framing, stain drywall and cause mold growth. Good Caulk Lines also reduce drafts and can improve energy efficiency around windows and exterior trim. Poor caulk work, even in small amounts, can become an open invitation for water and pests. A consistent approach to creating Caulk Lines saves time on repairs and keeps a project looking professional.

Types of Caulk and How They Affect Caulk Lines

Not all caulk is the same. Acrylic latex is easy to tool and paint and makes neat Caulk Lines for interior trim. Silicone is flexible and resists water but is harder to tool and cannot be painted. There are hybrid formulations that aim to combine the best traits. The choice of caulk matters because it impacts how easily you can shape a straight line and how the line will perform over time.

For wet areas choose a product labeled for baths and showers. For joints that will receive paint pick a paintable formula. For metal to glass joints select a silicone product that adheres to those surfaces. When picking materials consider shrinkage and cure time since these factors affect the final look of your Caulk Lines.

Tools That Help You Achieve Perfect Caulk Lines

Having the right tools makes creating good Caulk Lines simple. A quality caulk gun with a smooth squeeze delivers consistent flow. Utility knives and small stiff brushes help with surface cleaning. A foam pad or a specially designed caulk finishing tool will shape and compress the bead into a uniform line. Many professionals wet a finger lightly to smooth lines but be mindful of contaminants on skin that could mar a finish.

For quick access to tools and product comparisons consider checking product pages at Zoopora.com where you can review options for caulk guns and finishing kits. Choosing a tool that fits your hand and your project will make it easier to create steady Caulk Lines.

Surface Preparation: The Foundation of Clean Caulk Lines

Preparation determines about half the success of your Caulk Lines. Remove old caulk fully using a plastic scraper or a utility blade for stubborn sections. Clean all surfaces of dirt, soap film and mildew. Use a mild cleaner and a cloth to dry the joint before applying new material. For porous surfaces wipe with a solvent recommended by the caulk maker and allow full evaporation. If gaps are deep fill them with backer rod before applying caulk so that the caulk bead sits at the right thickness for optimal adhesion and flexibility.

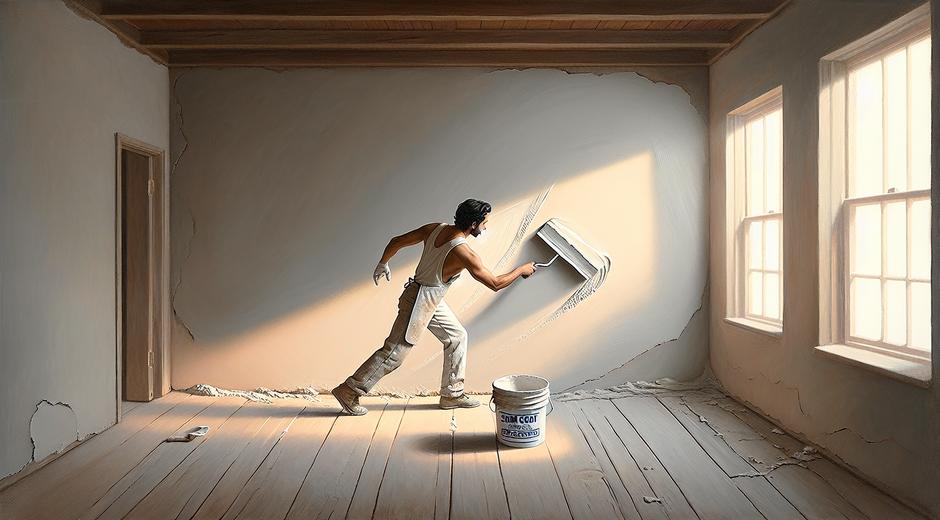

How to Apply Caulk for Straight Even Caulk Lines

Follow these steps for consistent Caulk Lines:

1 Choose the right tip size for the gap. A small opening needs a small tip to avoid excess material. 2 Cut the nozzle at a slight angle to allow easy placement of bead. 3 Hold the gun at a consistent angle and apply steady pressure while moving along the joint. 4 Tool the bead while the caulk is still wet. Use a damp finger, a foam pad or a plastic tool to smooth the bead into a neat line. 5 Remove any masking tape right away if used so the edge is crisp. 6 Allow full cure time before exposing the joint to water or paint.

Tooling is the most important step to achieve uniform Caulk Lines. Compressing the bead ensures good contact with both sides of the joint. A properly tooled line will shed water and hide minor surface imperfections so the seal looks clean and lasts longer.

Troubleshooting Common Problems with Caulk Lines

Problem 1: Uneven bead. Cause: inconsistent gun pressure or wrong nozzle. Fix: practice applying beads on scrap material, adjust the nozzle opening and maintain steady motion.

Problem 2: Poor adhesion. Cause: dirty surface or incompatible material. Fix: remove the bead, clean thoroughly and use a primer or select a caulk suited to the surfaces in question.

Problem 3: Cracking as it cures. Cause: sealer applied too thick or movement in joint. Fix: use a backer material to control thickness and select a more flexible caulk if the joint moves.

Finishing Tips for Picture Perfect Caulk Lines

Use masking tape on both sides of a joint to protect adjacent surfaces and peel it off as soon as you finish tooling to reveal razor sharp edges. Keep a wet rag handy for quick cleanups and to remove stray smears before the caulk skins over. For painted joints choose a paintable caulk and allow recommended drying time prior to painting. If color matching matters pick a caulk that closely matches the surface or use paintable varieties after cure.

Maintenance and When to Replace Caulk Lines

Inspect Caulk Lines annually in critical areas such as showers, tubs and exterior joints. Look for signs of mold discoloration, cracking and separation. Small sections can be removed and re caulked. For large failing sections it may be faster to remove the entire bead and replace it. Routine cleaning will keep joints healthy. Avoid harsh cleaners that degrade caulk polymers. Use mild soap and water or a cleaner recommended by the caulk manufacturer.

When to Call a Professional

Most Caulk Lines can be repaired by a dedicated homeowner. However call a professional when you find repeated failures, obvious structural movement, signs of rot behind the joint or when the joint spans unusual materials. Professionals can diagnose underlying causes and provide solutions that save time and money in the long term.

Step by Step Project Example for a Bathroom Tub

1 Remove the old bead completely with a scraper. 2 Clean the joint and dry thoroughly. 3 Place backer rod in deep gaps if needed. 4 Load a caulk tube rated for bathrooms into the gun. 5 Cut the nozzle for a bead slightly wider than the gap. 6 Apply a smooth consistent bead while moving at a steady pace. 7 Tool the bead with a wet finger or foam tool keeping steady pressure. 8 Wipe off residue and remove tape if used. 9 Allow full cure time before shower use.

Learn More and Find Other Repair Guides

For more tips about sealing, finishing and a wide range of home repair topics visit fixolix.com. You will find step by step tutorials, product guides and advice to help you create durable and attractive Caulk Lines and finishes across your home.

Final Thoughts

Caulk Lines are a simple detail that yields high value. With the right material, good surface preparation and a little patience you can achieve professional looking results. Regular inspection and maintenance will keep lines intact and protect your surfaces from moisture and air leaks. Whether you are working on cabinetry, bathrooms or exterior trim, the right approach to Caulk Lines makes a big difference in appearance and performance.