Expansion Joints A Comprehensive Guide for Design Selection and Maintenance

What Are Expansion Joints and Why They Matter

Expansion Joints are engineered components that absorb movement and accommodate dimensional changes in structures and piping systems caused by temperature variation load shifts and settling. They protect integrity and safety by preventing stress build up that can lead to cracks leaks or catastrophic failure. Whether you work on bridges buildings pipelines or mechanical systems a clear understanding of Expansion Joints improves reliability and reduces repair cost.

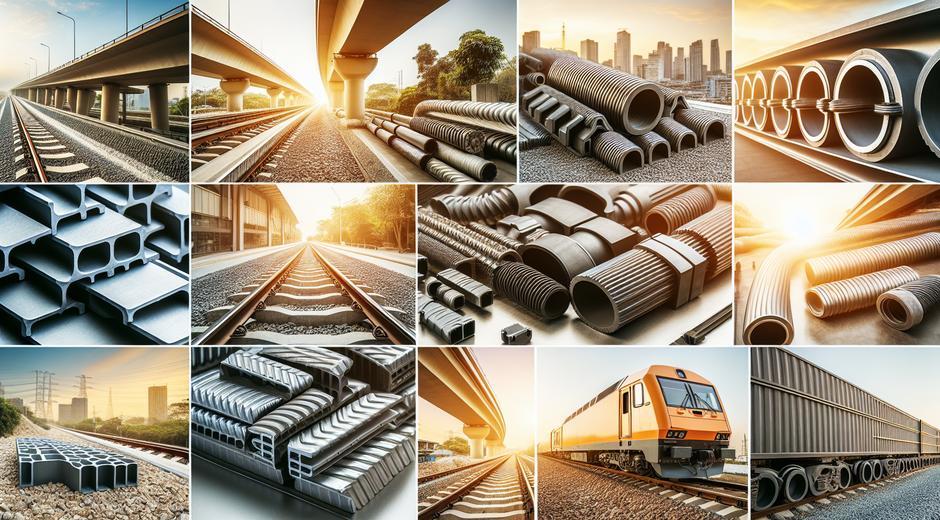

Common Types of Expansion Joints and Their Uses

There are several types of Expansion Joints each suited to specific applications and movement types. Knowing the main categories helps in selecting the right solution.

– Bellows Expansion Joints These metallic units are made of one or more corrugated elements that flex to absorb axial lateral and angular movement. They are common in high temperature or pressure piping.

– Rubber Expansion Joints Flexible elastomer bodies reinforced with fabric or metal provide vibration isolation noise reduction and compensate for moderate movement in water and chemical systems.

– Fabric Expansion Joints Lightweight textile elements handle thermal movement in ducts and flue gas systems where metallic bellows may be impractical.

– Modular Expansion Joints Used in large bridge decks and heavy duty structures these joints manage large movement with multiple linked plates and seals.

– Sliding Joint Types These rely on sliding surfaces combined with seals to allow linear movement in long pipelines or conveyor structures.

– Hinged and Gimbal Joints These make directional control of movement possible while resisting pressure thrust in piping networks.

Each type has advantages and limitations. For example bellows excel under extreme temperature while rubber joints are cost efficient for vibration control in pumps and fan systems.

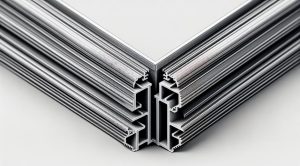

Key Design Considerations

Selecting the correct Expansion Joints requires evaluating several factors that affect performance and life span.

Material Compatibility Consider media type temperature range and chemical exposure. Metals offer high strength at elevated temperature while elastomers handle shock and noise with better corrosion resistance in certain fluids.

Movement Range Define the expected axial lateral and angular movement along with any combined motion. Over design leads to unnecessary cost under design creates failure. Look for manufacturer movement charts and certification data.

Pressure and Temperature Conditions Ensure the joint rating exceeds system operating conditions and includes safety margin. Also check for cyclic thermal load that can cause fatigue.

Mounting and Space Constraints Some joints require anchors or guides while others need space for travel. Plan layout to avoid interference and to allow inspection access.

Installation Orientation and alignment influence life time. Improper installation causes premature wear leaks and gasket failure.

Regulatory and code requirements Many installations must meet industry standards and local codes. Consult relevant piping or structural standards during selection.

Installation Best Practices

Correct installation maximizes useful life and minimizes downtime. Follow these general guidelines.

– Pre inspect components for damage or foreign objects before lifting into place.

– Confirm piping alignment and use guides to control movement direction.

– Do not apply compressive force beyond the weld neck or bolt flange.

– Tighten bolts using recommended torque sequence and avoid over torque.

– Allow for thermal pre compression or expansion as specified by the manufacturer.

– Provide access for inspection and maintenance.

Proper handling during installation prevents common issues such as fold distortion seal extrusion and premature fatigue of the corrugations.

Maintenance Inspection and Troubleshooting

Routine inspection reduces unexpected failure. A planned maintenance program should include visual checks and functional tests.

Look for signs of wear corrosion burn marks or cracking at weld zones and bellows crests. Check for leaks around flanges and verify that anchors and guides are intact. For rubber joints inspect for surface cracking material hardening and loss of elasticity.

If movement exceeds expected limits or vibration increases investigate root cause rather than replacing the joint alone. Address misalignment thermal restraints or pressure surges that may be stressing the joint.

When a joint requires replacement select a unit with equal or better performance and ensure installation follows original design criteria.

Common Failure Modes and How to Avoid Them

Understanding failure patterns helps avoid repeat problems.

– Fatigue Failure Repeated cyclic movement causes crack initiation in corrugations or welds. Use joints with adequate cycle rating and control movement amplitude.

– Corrosion Attack Material degradation from aggressive media can be mitigated by choosing resistant alloys lining or protective coatings.

– Seal Extrusion and Leakage Poor installation or excessive movement causes seal displacement. Ensure proper guidance and correct material selection.

– Mechanical Damage Handling or impact during installation can deform the joint. Use protective covers and follow lifting guidelines.

Addressing these factors in design and maintenance reduces lifecycle cost and improves uptime.

Applications Across Industries

Expansion Joints are found in many sectors.

– Bridge Construction They allow traffic decks and structural elements to move without damage.

– Power Plants High temperature steam piping relies on metal bellows to absorb thermal growth.

– Oil and Gas Pipelines Joints compensate for ground movement and thermal expansion along long runs.

– HVAC and Ductwork Fabric and rubber joints reduce noise and allow thermal drift.

– Marine and Shipbuilding Flexible joints absorb hull movement vibration and thermal change.

Selecting the right joint depends on unique operational demands and exposure conditions in each sector.

Standards Certification and Quality Control

Industry standards govern design testing and manufacturing of Expansion Joints. Familiar standards include those from international and national organizations that define pressure ratings movement capability and testing methods. Always request manufacturer certification testing reports and traceability documentation during procurement.

Quality control at the factory level includes nondestructive testing dimensional inspection and pressure testing. On site acceptance tests can include hydrostatic or pneumatic tests as applicable.

Cost Considerations and Lifecycle Value

Initial purchase cost is only one element of total cost. Consider installation cost maintenance intervals expected life and energy or downtime savings delivered by better performance. In many cases investing in a higher grade joint reduces long term expense and increases operational safety.

When planning budgets factor in spares lead time and local service support. For critical assets it is wise to keep replacement units on hand or to contract a service provider for rapid response.

Learning Resources and Expert Support

Expanding practical knowledge about Expansion Joints helps teams specify and maintain these components with confidence. For general fixing guides and a broad range of repair topics visit fixolix.com which offers step by step resources for installers and maintenance staff. For technical training and certification courses consider visiting StudySkillUP.com where you can find structured learning paths on mechanical systems design and inspection.

Final Recommendations

Choosing the right Expansion Joints requires balancing movement capability material compatibility pressure temperature and installation constraints with a clear maintenance plan. Engage with reputable manufacturers request test documentation and follow industry standards to ensure safety and reliability. Regular inspection and prompt corrective action prevent small issues from becoming major repairs. By integrating proper design and upkeep you extend service life reduce downtime and protect your investment.

If you need help with selection or a tailored maintenance checklist for a specific application contact a qualified engineer and gather application data such as movement range operating pressure and temperature before procurement.