Floor Screed A Complete Guide for Installers and Homeowners

Floor screed is a vital layer in any flooring system. It creates a flat and stable surface that receives the final floor finish such as tile, wood, or resin. Whether you are a professional installer or a homeowner planning a renovation, understanding floor screed helps you choose the right material and method for long term performance. For more practical repair and maintenance insights visit fixolix.com which offers tips across all fixing categories.

What Is Floor Screed and Why It Matters

Floor screed is a mixture of cement sand and water that is applied over a structural slab to create a smooth level surface. It is not a final finish. Instead it is a preparatory layer that ensures a uniform plane and provides adequate strength to support the final floor covering. The right screed prevents cracks, reduces differential movement and allows adhesives and finishes to bond correctly. A poorly installed screed can lead to uneven finishes moisture problems and costly repairs.

Common Types of Floor Screed

There are several types of floor screed each suited to specific needs. Understanding the difference helps you select the best option for your project.

- Traditional cement sand screed This is the most common type formed from a mix of cement and sand. It is durable and works well for general applications.

- Flowable screed Also called liquid screed. It is pumpable and self levelling during placement which speeds up large installations.

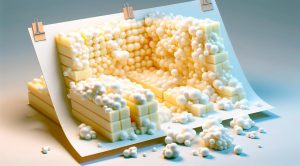

- Anhydrite screed Based on sulfoaluminate or calcium sulphate binders. It is smooth and ideal for underfloor heating because it has good thermal conductivity and does not require mechanical compaction.

- Polymer modified screed Contains polymer additives to improve flexibility adhesion and resistance to water. It is useful in areas that face moisture or higher stress.

- Fast drying screed Special mixes that reduce waiting time before installing the final floor finish. They are useful when time is limited but they may cost more.

Choosing the Right Thickness and Mix

Thickness depends on the type of screed and the use of the floor. Typical thickness ranges from 25 to 65 mm for bonded and unbonded screeds while floating screeds placed over insulation or membranes may require greater thickness to achieve design strength. A key factor is load and movement. Heavy loads or point loads require a thicker stronger screed. Mixing ratios for traditional screeds vary but common practice is one part cement to three or four parts sand by volume. Flowable and anhydrite screeds have proprietary formulas and are supplied with manufacturer guidance.

Preparation of the Substrate

Good substrate preparation ensures a durable screed. The slab must be clean free of dust and oils. Any cracks should be repaired and the surface primed where a bonding screed is needed. For bonded screeds the concrete is usually dampened but not left with standing water. For unbonded and floating screeds separation layers such as polythene sheets and insulation boards provide a clean interface between screed and structure. Control joints or movement joints are planned to match structural joints in the slab and to allow for thermal movement.

Mixing Placement and Finishing

For hand mixing always follow the recommended proportions and maintain consistent water content to avoid weak spots. For large areas pump mixed screeds ensure the supplier sets the correct water to cement ratio before delivery. Placement should be done in continuous runs to avoid cold joints. Compacting and screeding off should be done with the correct tools to get an even level. Finishing techniques differ by type. Cement sand screeds are often trowelled once they firm up while flowable screeds level by themselves and only need light finishing. Overworking the surface can cause cracking and dusting so follow recommended curing practices.

Curing Time and Moisture Control

Curing is critical to strength development. Traditional cement screeds require moist curing for several days to reduce shrinkage and improve strength. Anhydrite and fast drying screeds have different protocols and often allow earlier installation of floor finishes. Measuring residual moisture with a moisture meter or by using a calcium carbide test helps determine when a finish can be applied. Too much moisture can cause adhesive failure floor buckling or mold growth when the finish is installed prematurely.

Using Floor Screed with Underfloor Heating

Underfloor heating systems work best when covered by a screed that transmits heat efficiently. Anhydrite screeds are popular for this application because they flow around pipes and form a continuous layer with good thermal conductivity. When using cement based screeds it is important to pre wet the screed and follow a gradual heating up protocol to avoid thermal shock. The right screed thickness and good contact with heating pipes ensures efficient heat transfer and even floor temperatures.

Common Problems and How to Avoid Them

Many issues stem from poor preparation or incorrect materials. Common problems include cracking due to rapid drying or inadequate curing inadequate bond between screed and substrate incorrect water content and poor mixing. To avoid these problems check substrate readiness use quality materials follow manufacturer guidance for mixed products and implement proper curing. If cracks do appear assess whether they are structural or surface level and choose an appropriate repair method such as injection or surface repair mortars.

Tools and Equipment Needed

Basic tools include a mixing bucket or mixer trowels and straight edges for leveling. For larger jobs pump delivery of flowable screed reduces labor and ensures consistent mix quality. Other equipment like vibrating screeds or screed lasers improves accuracy and finish quality. Personal protective equipment such as gloves eye protection and kneepads helps keep workers safe during installation.

Cost Considerations and Value

Costs vary depending on the type of screed area size and whether the work is done by a contractor or as a DIY project. Flowable and specialist screeds typically cost more per square meter but reduce labor time and can offer quicker turnaround. Consider the total life cost not just initial outlay. A well installed screed reduces the risk of floor failure and protects the investment in high quality finishes. For trend ideas and interior inspiration related to flooring visit StyleRadarPoint.com which features layouts and styling tips that work with modern screed based floor systems.

Selecting a Contractor

Choose a contractor with specific experience in floor screed installation. Ask for references examples of completed work and details on materials used. Confirm the contractor follows testing and curing protocols and offers a warranty on workmanship. A reputable installer will also provide guidance on the right screed type for your use case whether it is a domestic renovation or a commercial project.

Maintenance and Long Term Care

Screed itself needs little maintenance if it is covered by a finish. Preventative care for the final floor covering helps protect the screed from moisture ingress and heavy impact. If a repair is needed address it promptly to prevent propagation of damage to the substrate. For floors with underfloor heating occasional checks of system performance and moisture levels are recommended.

Final Thoughts

Floor screed is the unsung hero of a successful flooring system. Choosing the correct type preparing the substrate properly and following recommended curing practices ensure a long lasting flat surface ready to receive the final finish. Whether you opt for a traditional cement screed a flowable self levelling product or an anhydrite mix the key is correct installation and quality control. For repairs and a broad selection of fixing tips across different categories remember to consult trusted resources and experienced professionals to protect your investment and achieve the desired finish.