Subfloor Joists: Complete Guide to Inspection Repair and Best Practice

Subfloor joists are the backbone of any floor system. Understanding how they work where they are used and how to maintain them is vital for anyone involved in home repair renovation or construction. This guide covers everything from basic anatomy to advanced repair methods and inspection checklists so you can keep floors level safe and quiet for years to come.

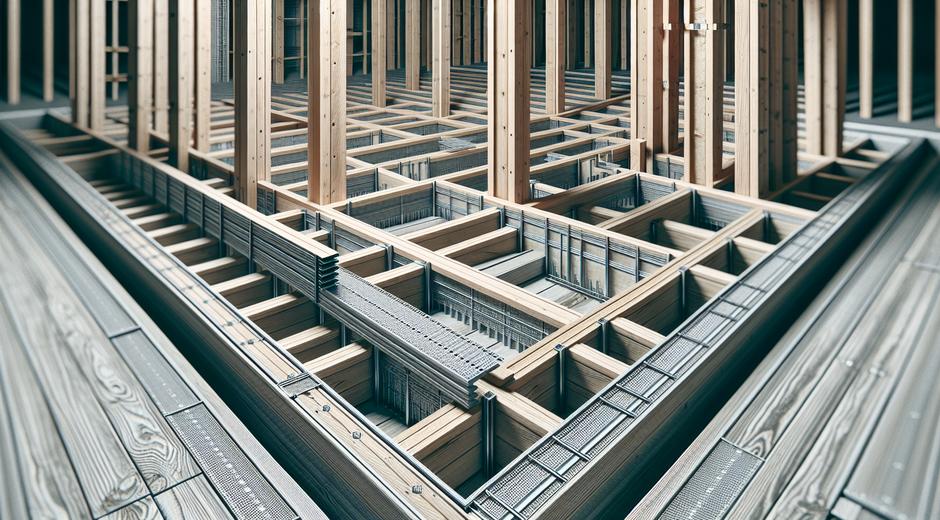

What Are Subfloor Joists and Why They Matter

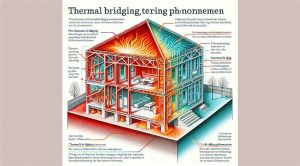

Subfloor joists are horizontal structural members that span between supports such as beams walls or columns and carry the subfloor and finish floor load. They transfer weight to the foundation and provide a rigid platform for floor coverings. Poorly installed or damaged subfloor joists can lead to sagging floors uneven surfaces squeaks and even structural risk. Regular attention to joist health prevents small problems from turning into costly repairs.

Common Materials Used for Subfloor Joists

The most common material for joists is solid sawn lumber often timber of species such as pine fir or spruce. Engineered lumber options include laminated veneer lumber and I joists which use a thin web of oriented strand board or plywood between two top and bottom flanges. Each material has benefits and trade offs. Solid lumber is familiar easy to alter and often lower cost. Engineered joists resist warping and can span longer distances with less depth which is useful when ceiling height is limited.

Standard Sizes and Spacing for Subfloor Joists

Size and spacing depend on span load and flooring type. Common dimensions include two by eight two by ten and two by twelve for solid lumber. Spacing is often sixteen inches on center or twenty four inches on center. Closer spacing increases rigidity and reduces deflection which helps prevent cracking of brittle floor coverings. Always consult local building code and a structural engineer for unusual spans high loads or when converting spaces to heavier uses like a gym or hot tub room.

How to Inspect Subfloor Joists

A thorough inspection begins with a visual survey and simple tests. Look for sagging or uneven floors and check for soft spots by walking across the surface. From below inspect for cracks splitting rot insect damage or signs of water staining. Pay attention to connections at beams and joist hangers and look for missing or loose fasteners. Listen for squeaks which often indicate movement between joist and subfloor or between joist and hanger.

Tools that make inspection easier include a flashlight a small pry bar a moisture meter and a voice recorder to note locations for repair. If you find discoloration test for moisture to determine if the source is active. Active moisture must be addressed before structural repair to avoid repeat damage.

Common Problems with Subfloor Joists and How to Fix Them

Rot is a frequent problem in joists exposed to moisture. If damage is limited to a small section repair options include replacement of the affected board or sistering a new joist alongside the existing member using bolts or screws to transfer load. Sistering provides added strength without full removal and is effective when decay is localized.

Cracks splits and checks in joists can often be repaired by fastening plywood plates to both faces of the joist or by installing a steel plate in more severe cases. Ensure repair plates are continuous across undamaged wood and that fasteners penetrate adequate thickness to hold securely.

Squeaks result from movement where the subfloor meets the joist. Solutions include tightening fasteners adding blocking between joists to reduce movement or applying construction adhesive at the top of the joist where subfloor meets joist. In many cases a few well placed screws through the floor into the joist will eliminate the noise.

When to Replace Subfloor Joists

Replacement is necessary when damage compromises structural capacity across a significant length or when multiple joists are affected. Signs that indicate full replacement include wide sag over long spans extensive rot or insect damage and cases where repair would be more expensive than replacement. Always follow local code and consider professional advice for load bearing members and for projects involving removal of load paths.

Best Practice for Joist Repair and Strengthening

When repairing or strengthening follow these best practice steps. First diagnose the root cause especially moisture then fix the cause. Use pressure treated lumber where exposure to moisture is possible. Fasten new material with approved structural screws or bolts and use joist hangers that match the joist size. Add blocking or bridging between joists to spread load and reduce rotation. For major upgrades consider replacing with engineered joists which often offer greater strength for the same depth.

Tools and Materials You Will Need

Common tools for joist work include a circular saw a drill and driver a reciprocating saw a pry bar a level and clamps. Materials vary with the repair but typically include joist hangers structural screws or bolts construction adhesive plywood for skin plates pressure treated lumber and metal connectors. Always use connectors rated for the intended load and suitable for contact with treated wood.

Cost Considerations and Budgeting

Repair costs vary based on access degree of damage and choice of materials. Small local repairs such as sistering one joist often fall into an affordable range. Large scale replacement or conversion to engineered joists is more expensive but can add structural capacity and value. When budgeting include cost for moisture remediation if needed and for inspection by a qualified professional if loads are critical.

Safety Tips and Permits

Work that affects structural elements often requires a permit and may need an engineered plan. Always check local requirements before starting work. During repair protect yourself with safety glasses gloves and respiratory protection when cutting old wood that may contain dust or mold. Ensure shoring is in place when removing joists that carry loads and do not remove load paths without proper temporary support.

Frequently Asked Questions About Subfloor Joists

How often should I inspect joists? Inspect at least once a year and after any major leak or flood event. What causes most joist failures? Moisture and insect activity along with inadequate sizing for applied loads are common causes. Can I add new loads such as a heavy tub to an existing floor? You should consult a structural professional to confirm adequate capacity and to design any required reinforcement.

Where to Learn More and Find Help

For general home repair resources and guides on a wide range of fix tasks you can visit fixolix.com where there are articles tools lists and project guides designed for homeowners and trades. If you need to connect with local builders or contractors for larger projects check listings and resources at MetroPropertyHomes.com which can help you find professionals familiar with structural repair and renovation.

Final Thoughts on Subfloor Joists

A well maintained subfloor joist system is essential for a safe quiet and durable floor. Regular inspection timely repairs and choosing the right materials will extend the life of your floors and avoid expensive emergencies. When in doubt consult a professional and address moisture issues immediately. With the right approach you can keep floors solid and dependable for decades.