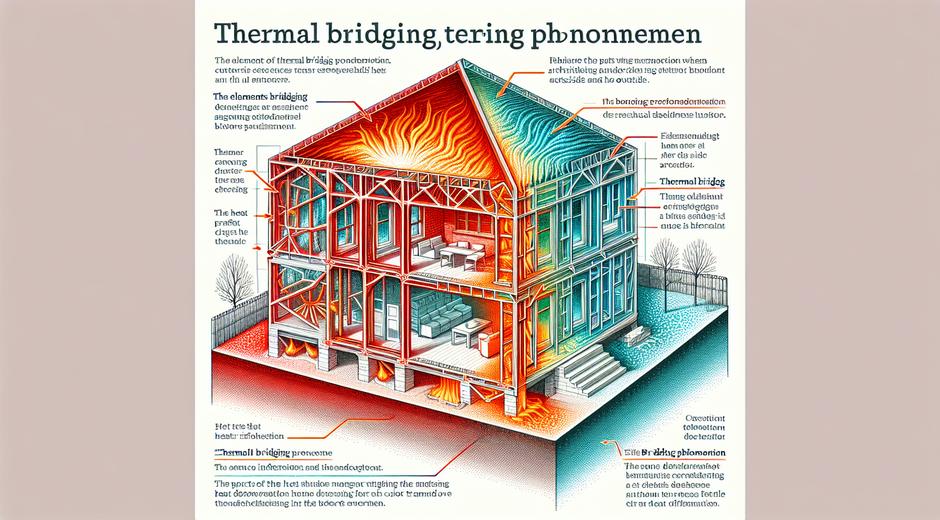

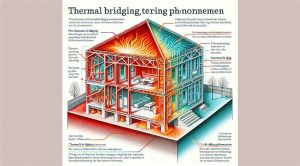

Thermal Bridging What It Is and How to Prevent It

Thermal Bridging is a common issue that undermines the performance of building envelopes and reduces overall energy efficiency. For homeowners contractors and building professionals understanding Thermal Bridging is essential to improve comfort extend the life of building components and lower heating and cooling costs. This article explains what Thermal Bridging is why it matters how to find it and practical methods to prevent it so that your projects deliver real value.

What Is Thermal Bridging

Thermal Bridging occurs when a material that conducts heat more rapidly than adjacent materials creates a path for heat flow through an insulation layer. This path can bypass insulation and cause heat loss in winter and heat gain in summer. Thermal Bridging can happen at junctions between walls and floors around window frames where structural members penetrate insulation and at fastener locations or other spots where continuity of insulation is broken. The result is localized cold spots increased condensation risk and higher energy bills.

Why Thermal Bridging Matters

Reducing Thermal Bridging is a top priority for high performance building design. In cold climates bridging can create surfaces that are much colder than surrounding areas. These cold spots lead to condensation and eventual mold growth which harms indoor air quality and can damage building materials. In mild climates bridging reduces the effectiveness of insulation and forces mechanical systems to use more energy to maintain comfort. For projects aiming for certifications or compliance with energy codes addressing Thermal Bridging is often required to meet performance targets.

Common Causes of Thermal Bridging

- Structural members that pass through the insulation layer such as metal studs and floor beams

- Metal window and door frames with poor thermal break detail

- Continuous masonry or concrete elements that connect interior and exterior faces

- Fasteners and anchors that pierce insulation layers without thermal break

- Poorly detailed junctions between walls roofs and floors that interrupt continuous insulation

How to Detect Thermal Bridging

Early detection helps avoid costly repairs. Common inspection and testing methods include visual inspection infrared thermography and blower door testing combined with a thermal camera. Infrared thermography reveals surface temperature differences that highlight cold spots where heat is escaping. A blower door test helps confirm air leakage that may be associated with bridging although not all Thermal Bridging is caused by air flow. During design phase thermal modeling can predict problem areas using software that calculates heat flow and identifies likely bridges.

Design Strategies to Prevent Thermal Bridging

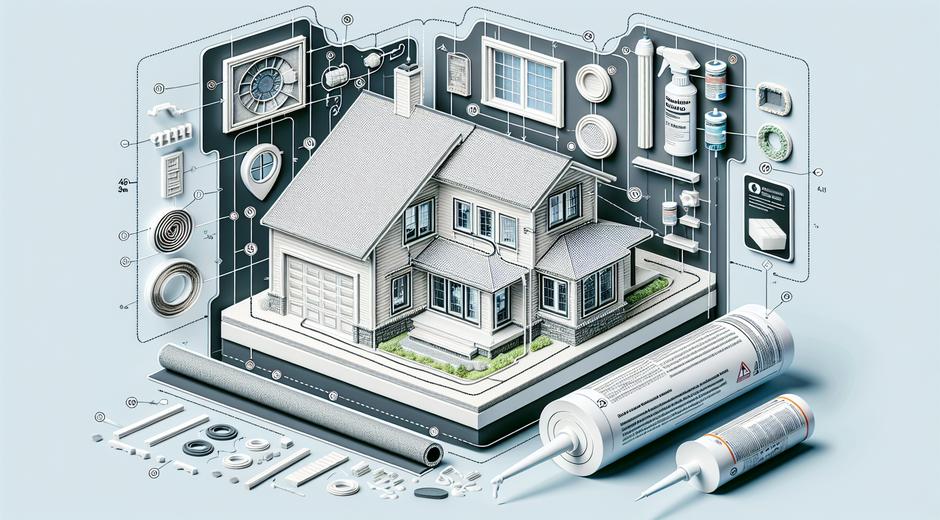

Good planning is the most cost effective way to reduce Thermal Bridging. Strategies include creating continuous insulation layers around the building using thermally broken structural connections and locating insulation on the outside of structural members where feasible. For example placing continuous rigid insulation over an exterior masonry wall ensures that the structure is inside the insulated envelope which reduces conductive paths. Designing window and door assemblies with integrated thermal breaks or using insulating spacers helps reduce conduction around openings.

Materials That Help Reduce Thermal Bridging

Choosing the right materials is key. Low conductivity materials such as wood and certain engineered plastics are less likely to cause major Thermal Bridging than metals. When metal is necessary use thermal break components such as insulated connectors or thermal pads. Insulation types matter too. Closed cell spray foam rigid board and high performance mineral wool offer good thermal resistance and can be applied continuously. Advanced composites and thermally broken metal assemblies provide solutions for challenging junctions while maintaining structural integrity.

Installation Best Practices

- Maintain continuous insulation across assemblies and carefully seal joints between insulation panels

- Place insulation outside of structural elements where possible to keep structures within the thermal envelope

- Use thermal break materials at points where fasteners or connectors penetrate the insulation

- Detail window and door openings to include insulation continuity and proper flashing to avoid moisture trapping

- Train installers to understand on site compromises that can create unintended thermal paths

Cost Benefits of Controlling Thermal Bridging

Investing in proper detailing and materials to reduce Thermal Bridging pays back through lower energy bills improved occupant comfort and reduced risk of moisture damage. While some measures such as exterior continuous insulation or thermally broken frames add upfront cost they often reduce the size and runtime of heating and cooling equipment and lower maintenance and repair expenses over time. For new construction and major renovations modeling can quantify expected energy savings and help build a compelling financial case.

Regulations Standards and Certification

Building codes and green building programs increasingly require attention to Thermal Bridging. Many energy codes outline acceptable methods to account for bridging in compliance paths and some certification programs reward designs that minimize thermal pathways. When working on projects intended for certification or code compliance consult local requirements and use modeling tools to provide evidence that bridging has been taken into account. Professional third party verification can also strengthen compliance claims and improve occupant confidence.

Practical Case Examples

A mid rise office building upgraded exterior insulation and installed thermally broken balcony connectors. The upgrade reduced surface condensation and lowered heating energy use significantly. A residential retrofit applied continuous exterior insulation to a brick veneer wall and corrected cold spots around window frames resulting in improved comfort and fewer mold complaints from occupants. These examples show that targeted measures deliver meaningful improvements without requiring a complete redesign of the building.

Tools and Resources

There are many practical tools to evaluate and address Thermal Bridging. Infrared cameras are essential for field diagnostics while thermal modeling software helps predict performance in design stage. For product selection consult manufacturer details on thermal break performance and service life. For a broad selection of guides methods and practical tips visit fixolix.com where you will find a range of articles and repair guides that cover building envelope issues and best practices for construction and retrofit projects.

Partnering with Experts

When projects are complex bring together architects engineers and experienced installers early in the process. Collaboration ensures that structural needs are met while optimizing thermal performance. For designers seeking case studies and recommended products explore external resources such as industry blogs and specialist sites that share installation examples and product reviews. One useful resource for broader building and material insights is SportSoulPulse.com which often features industry perspectives and product information that can inform better decision making.

Frequently Asked Questions

What is the difference between Thermal Bridging and air leakage Thermal Bridging is about conductive heat flow through materials while air leakage involves convective heat transfer through gaps and cracks. Both can occur together and both reduce energy performance. How much can Thermal Bridging affect overall energy use The impact varies with design climate materials and quality of installation but it can be substantial often increasing heat loss by a noticeable percent if not addressed. Can existing buildings be fixed Yes many retrofit measures exist from adding exterior insulation to replacing or modifying window frames and improving junction details.

Conclusion

Thermal Bridging is a technical but solvable challenge. By understanding how heat finds paths through building components and by using continuous insulation thermally broken connections and careful installation you can significantly improve energy performance building durability and occupant comfort. Whether you are planning a new build or a retrofit attention to Thermal Bridging will protect your investment and reduce long term costs.

If you need detailed step by step guidance on common fixes or want to explore specific product recommendations visit the resources mentioned above and consult professionals who can model and inspect your site for targeted solutions.