Wall Insulation Types: A Practical Guide to Picking the Right Option for Your Home

Insulating walls is one of the most effective ways to improve comfort and reduce energy costs in any building. Understanding Wall Insulation Types helps homeowners and professionals choose materials that match climate, budget and construction constraints. This guide covers the main options, their benefits and considerations so you can make an informed choice for your next project.

Why Wall Insulation Matters

Good wall insulation reduces heat loss in winter and heat gain in summer. It improves thermal comfort, cuts energy bills and can reduce noise transmission between rooms. Different Wall Insulation Types offer varying performance for thermal resistance, moisture control and ease of installation. Selecting the best type can also extend the life of heating and cooling equipment and increase overall building value.

Key Factors to Consider Before Choosing

Before comparing Wall Insulation Types, assess the following:

– Climate and typical seasonal temperature extremes in your area

– Whether walls are timber frame, masonry or metal stud

– Space available inside cavity or on internal face

– Budget for materials and labor

– Desired lifetime and maintenance needs

– Fire safety and moisture control requirements

A short site inspection can reveal whether cavity filling is possible or if internal or external options are more practical. For project planning and quick resources about fixing and home improvement topics visit fixolix.com where you will find detailed articles and tool guides.

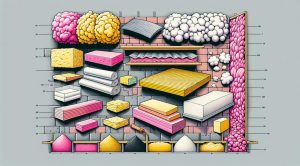

Common Wall Insulation Types

Below are the most widely used Wall Insulation Types with the advantages and limitations of each.

Fiberglass Batts and Rolls

Fiberglass batts and rolls are made from fine glass fibers and are commonly used in framed walls. They are affordable and easy to install for DIYers when walls are open. Key benefits include fire resistance and non corrosive properties. Performance depends on correct fit and avoiding gaps or compression. If batts are crushed or poorly cut around pipes and wiring thermal performance will drop. Batts are available in different thicknesses to meet required R values. In humid climates consider a vapor control layer to limit moisture migration.

Mineral Wool

Mineral wool comes in batts or as loose fill and is valued for sound control and fire resistance. It holds its shape and resists settling better than some loose materials. Mineral wool is denser than fiberglass which gives better acoustic performance and improved thermal performance per unit thickness. It is a good choice where noise control between rooms is important. Like other fibrous products, proper installation to avoid gaps is crucial.

Blown in Loose Fill

Blown in loose fill materials include cellulose and fiberglass. Cellulose is often made from recycled paper treated for fire and pest resistance. Blown in systems are ideal for filling cavities and irregular spaces and can be used for retrofits without removing internal finishes. Proper installation requires equipment to ensure uniform density. Loose fill tends to settle over time so initial installation density is important to maintain long term performance.

Spray Foam Insulation

Spray foam comes in open cell and closed cell varieties. Open cell is softer and provides good air sealing with a lower R value per inch. Closed cell has a higher R value and is more rigid. Spray foam is effective where air sealing and high thermal resistance are priorities. It can also add structural rigidity in some assemblies. Considerations include higher material and installation cost and the need for trained applicators. Ventilation and curing time must be observed during installation to protect indoor air quality.

Rigid Foam Boards

Rigid foam boards such as expanded polystyrene, extruded polystyrene and polyisocyanurate are widely used for external insulation and cavity insulation. They offer consistent thermal resistance and are water resistant when sealed properly. Boards can be cut to fit and provide a continuous insulation layer that minimizes thermal bridging through studs and masonry. Installation often requires adhesive, mechanical fasteners or special fixings. For exterior cladding projects rigid foam boards combine well with weather barrier layers.

Insulated Panels

Insulated panels combine a core of foam with protective faces of metal or composite sheeting. These panels can be used for both internal and external wall systems and offer rapid installation for new builds. Panels provide predictable thermal performance and can include profiles for airtight joints. They are commonly used in commercial and industrial applications but are increasingly used in residential projects for speed and performance.

Natural and Sustainable Options

Natural materials such as sheep wool, cork and hemp are gaining interest due to low embodied energy and potential for better indoor air quality. Sheep wool is hygroscopic which helps moderate humidity. These sustainable Wall Insulation Types can be slightly higher in cost and may require pest and moisture considerations but they appeal to environmentally conscious homeowners.

Comparing Thermal Performance and R Values

When evaluating Wall Insulation Types look at R value per inch and how the material performs in assemblies. Materials with high thermal resistance per unit thickness are useful where space is limited. However overall performance depends on air sealing and correct installation. Airtightness and continuous insulation around framing reduce thermal bridging which can otherwise undercut the predicted thermal benefit.

Moisture and Fire Considerations

Moisture control is critical to avoid mold and structural damage. Some materials manage moisture well while others require vapor control layers. Fire performance varies widely between Wall Insulation Types. Mineral based products offer high fire resistance while some foam products need protective layers to meet building codes. Consult local codes and a building professional when choosing insulation for safety compliance.

Cost and Lifecycle Factors

Initial cost varies from low cost fibrous products to higher cost spray foam and insulated panels. Consider lifecycle savings from energy reduction and potential incentives or rebates. More durable materials with stable performance often justify higher initial cost. Routine inspection and addressing of any gaps or deterioration helps maintain long term performance.

Installation Best Practices

Proper installation maximizes the benefits of any chosen material. Best practices include:

– Ensuring cavities are clean and dry before installation

– Avoiding compression of fibrous materials

– Providing continuous insulation where possible to limit thermal bridging

– Sealing gaps to improve airtightness

– Using protective layers when required by code for fire safety

When in doubt hire a qualified installer who understands wall assemblies and how to integrate insulation with air and moisture control.

Choosing the Right Wall Insulation Type for Your Project

Select the Wall Insulation Type that matches your priorities. For budget conscious retrofit work consider blown in cellulose or fiberglass. For high performance and air sealing consider spray foam or rigid foam boards. For sound control and fire safety mineral wool is very effective. For a balance of sustainability and thermal performance explore natural fibers.

If you are planning a project and want a quick library of how to fix common issues along with product guides and tool recommendations check Moviefil.com where you can find curated resources and installation videos that complement written guidance.

Conclusion

Understanding Wall Insulation Types empowers better decisions for comfort, efficiency and long term building health. Consider climate, wall construction, budget and performance goals when making a selection. Proper installation and attention to air and moisture control are as important as material choice. Investing time in planning yields predictable savings on energy bills and improved comfort year round.

For ongoing project support use available resources, consult building professionals and follow local code requirements to ensure safe and effective insulation outcomes.