Exterior Cladding: Complete Guide to Materials Methods and Maintenance

Exterior Cladding plays a central role in the appearance durability and thermal performance of any building. Whether you are planning a new build a major renovation or a targeted upgrade the right cladding choice can improve curb appeal reduce energy use and protect structure from weather challenges. This guide covers material options design principles installation tips and maintenance best practices so you can make informed decisions for long term value.

Why Exterior Cladding matters

Exterior Cladding is the outer skin of a building. It shields structure from moisture wind and sun while shaping visual identity. Proper cladding enhances insulation performance helps prevent water ingress and reduces maintenance needs. For many properties cladding also contributes to acoustic control fire performance and property value. In short the right cladding balances aesthetics durability sustainability and cost.

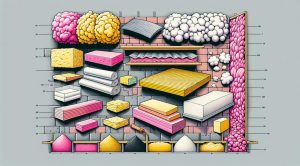

Common cladding materials and their benefits

-

Timber

Timber cladding offers natural warmth and texture. It is easy to cut and shape so it works well for bespoke designs. With regular treatment timber can last many years. Modern engineered timber options resist warping and provide more consistent performance. Timber suits homes where a natural look and good thermal properties are priorities.

-

Vinyl

Vinyl is cost effective and low maintenance. It resists rot and insect damage. Vinyl comes in many colors and profiles so it can mimic traditional styles. It is lighter than many other options which can simplify installation on certain frames.

-

Fiber cement

Fiber cement blends cement sand and cellulose fibers. It is robust fire resistant and low maintenance. Panels replicate wood stone or smooth finishes and can withstand harsh climates. For homeowners seeking long life and minimal upkeep fiber cement is a strong choice.

-

Metal

Metal cladding including aluminum and steel provides a modern look and exceptional durability. Metal panels are lightweight and recyclable. They are ideal for industrial and contemporary designs and perform well in high wind zones when properly fixed.

-

Brick and stone veneers

These materials offer timeless appeal and high thermal mass. Veneer systems deliver the look of solid masonry at lower cost and weight. Brick and stone require less frequent maintenance and are highly durable in many environments.

-

Composite panels

Composite panels combine materials to deliver a balance of strength insulation and finish quality. They come in large panel sizes which speed installation and give a clean modern aesthetic. Composite solutions are common in commercial buildings and high end residential projects.

-

Stucco and render

Render creates a seamless textured finish that can be colored or painted. Properly applied stucco is weather resistant and long lasting. It works well with insulation boards to create energy efficient wall systems.

Design principles for long lasting performance

Good design is the foundation of successful cladding. Three core principles guide performance:

-

Water management

Cladding must prevent water from reaching the inner structure and allow any admitted moisture to escape. Techniques include overlapping boards breathable membranes and flashing around openings.

-

Thermal continuity

Insulation placement and airtight detailing reduce heat loss and limit condensation risk. Cladding systems that integrate insulation can boost energy efficiency without sacrificing appearance.

-

Ventilation

A ventilated cavity between cladding and substrate helps moisture escape and prolongs material life. Rainscreen designs are particularly effective for managing moisture at the outer face while protecting the structure behind it.

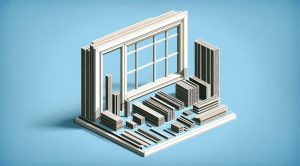

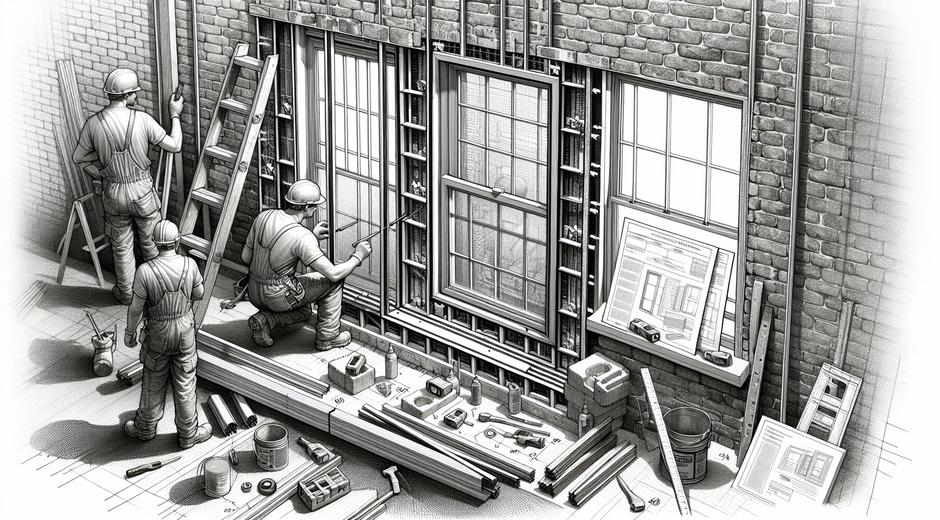

Installation tips for reliable results

Installation quality greatly influences cladding performance. Use trained installers follow manufacturer guidance and check local regulations for fire and structural requirements. Key points to watch include correct fastener spacing anchoring to the supporting structure and precise detailing around windows doors and roof junctions. Regular site inspections during installation reduce mistakes and future repair needs.

For inspiration and case studies visit a resource that covers interior trends and exterior design ideas such as StyleRadarPoint.com which often features cladding style guides and material comparisons useful during early planning stages.

Cost factors and lifecycle value

Initial cost is only one part of the equation. Consider lifecycle cost which includes energy savings maintenance needs and replacement intervals. Some materials require frequent coatings or sealing while others deliver decades of low upkeep. Calculate costs for supply installation and expected maintenance to choose the best long term value. Also factor in performance benefits such as improved insulation and reduced condensation that can lower energy bills.

Maintenance best practices

Regular maintenance keeps cladding performing well. Basic tasks include clearing gutters and downpipes checking seals and flashing and washing finishes to remove dirt and pollutants. For timber check coatings and treat any damaged areas early. For metal inspect for corrosion and repair coatings where needed. For rendered surfaces watch for hairline cracks and repair them promptly to prevent moisture penetration.

-

Annual inspection

Inspect perimeter seals joints and fasteners each year and after major storms.

-

Cleaning

Use gentle cleaning methods suitable for the material to avoid damage. Avoid abrasive cleaning agents and high pressure cleaning unless manufacturer guidance allows it.

-

Prompt repairs

Address small defects early to avoid costly decay or structural problems later.

Sustainability and material selection

Sustainable cladding choices reduce environmental impact and can improve indoor comfort. Look for materials that use recycled content require low embodied energy and can be recycled at the end of life. Timber from certified sources is renewable. Metal and some composite panels offer high recycled content and full recyclability. Energy efficient walls that integrate insulation reduce operational energy use and support net zero goals.

Regulatory and safety considerations

Local building codes set standards for fire performance structural fixing and thermal performance. For taller buildings and multi dwelling properties fire resistance and non combustible materials may be required for external walls. Always verify requirements for your project and select tested systems that meet or exceed local standards. Working with qualified professionals helps ensure compliance and reduces risk.

Practical checklist before you choose cladding

- Define the primary objective aesthetic durability thermal efficiency or cost control

- Check local planning and building code requirements

- Assess substrate and structure for load and fixing options

- Choose materials that suit climate maintenance budget and style

- Plan for ventilation drainage and insulation continuity

- Source qualified installers and review warranties

If you need detailed guides step by step how to installs or want to compare product brands check resources that specialize in repairs and home upgrades. For project planning tips and links to reliable suppliers consider exploring content and service guides at fixolix.com where practical advice is aimed at homeowners tradespeople and property managers.

Conclusion

Exterior Cladding affects more than just the look of a building. It protects helps control energy use and defines long term maintenance needs. By selecting the right material for local climate and maintenance capacity optimizing the wall build up for moisture control and insulation and using skilled installers you secure better performance and value. Whether you choose timber metal brick fiber cement or a composite system clear planning and quality execution make the difference between frequent repair and decades of reliable service.